(1) Brief introduction of main thermal systems 1. Water […]

(1) Brief introduction of main thermal systems

1. Water treatment system

"Industrial Boiler Water Quality" (GB1576-2008) is suitable for fixed tidy boilers with steam as the medium and equal to 2.5MPa, and steam and water boilers as well as fixed pressurized hot water with water Boiler and atmospheric hot water boiler.

(1) Softened water

There are two methods for softening water: adding potion in the pot and chemical water treatment outside the pot.

(2) Deoxygenation method

The deaeration method includes thermal deaeration, vacuum deaeration, desorption deaeration, chemical deaeration, steel shavings (sponge iron) deaeration, etc.

Atmospheric spray thermal deaerator should be used for boiler feed water.

The deoxidation of make-up water in the hot water system can be performed by vacuum deoxygenation or chemical deoxygenation.

2. Water supply system

Refers to the feed water of the steam boiler. Mainly include feed water tank, boiler feed water pump, etc.

3. Heating network circulating water system

Refers to the heating water network circulating water system of the hot water boiler, and is also the main system of the hot water boiler using the water circulation to provide external heat.

Mainly include circulating water pump, make-up water pump, decontamination device, etc.

4. Boiler blowdown system

Refers to the regular blowdown and continuous blowdown system of the boiler, the purpose is to exclude the condensed dirt in the boiler and the boiler water with excessive alkalinity.

Mainly include sewage valves, pipelines, outdoor sewage cooling pools, etc.

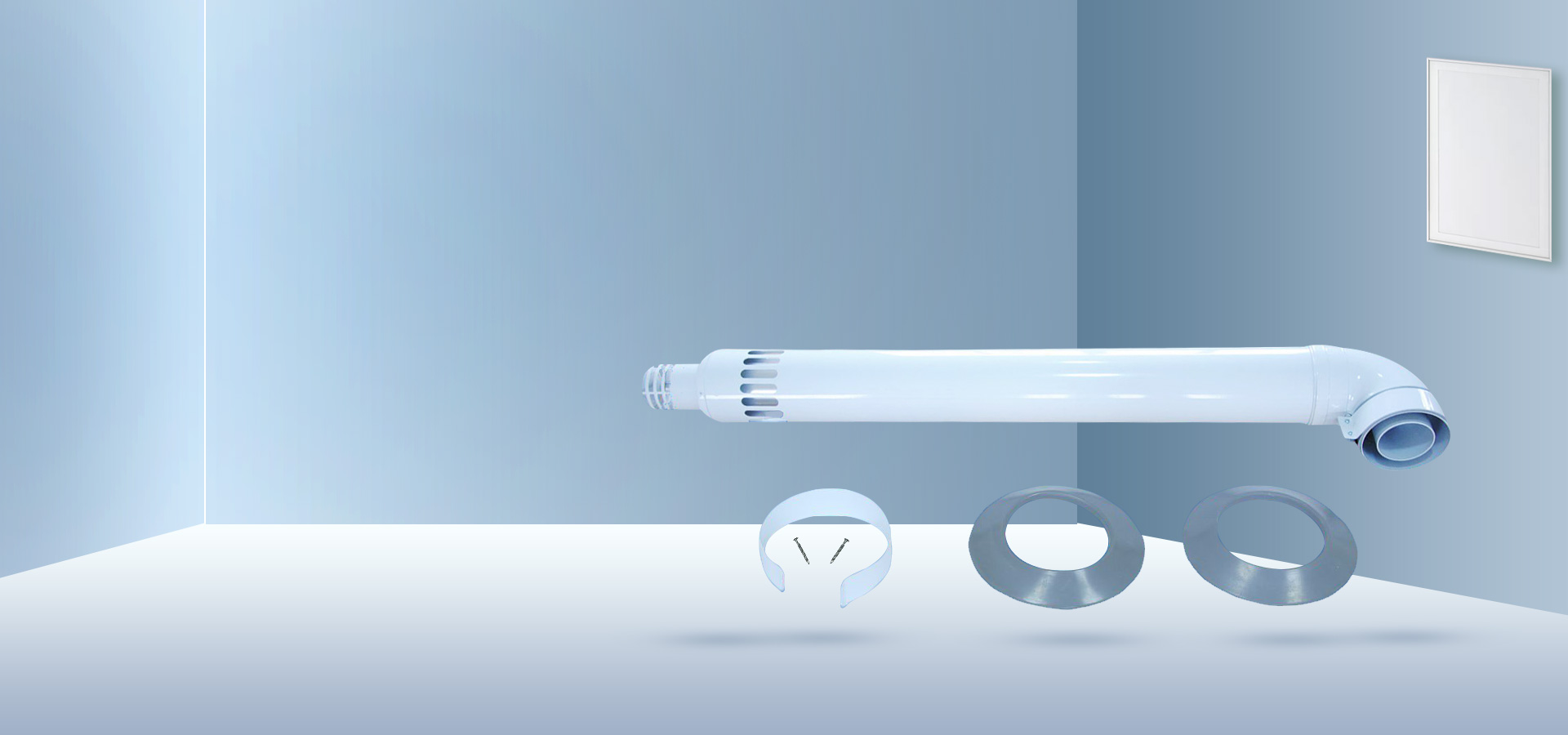

5. Wind smoke system

Refers to the supply of air required for boiler fuel combustion and the exhaust system of flue gas after combustion. It mainly includes air inlet or air inlet window, blower and air duct, flue, smoke muffler and chimney.

(2) Pressure relief area

Article 187 of "Steam Boiler Safety Technical Supervision Regulations", "The outer wall or roof of the boiler room should have at least a pressure relief area equivalent to 10% of the boiler room area (such as glass windows, skylights, weak walls, etc.) The place shall not be adjacent to rooms and passages with large crowds. "

(3) Combustible gas concentration alarm device and interlock

"Code for Design of Boiler Room" (GB50041-2008), gas pressure regulating room, gas boiler room and oil pump room should be equipped with combustible gas concentration alarm device.

(4) Fuel supply, pressure regulating device and metering device of fuel gas system